-

We offer three product lines: IN LINE, BEM, BEU exchangers

SHELL AND TUBE HEAT EXCHANGERS

Sicimi initially started production of shell and tube heat exchangers for internal needs, when, thanks to the experience gained in thermoregulation, it decided to design and produce these units. Given the results achieved over time it came naturally to also offer this type of product to the public, certain of being able to offer a product that fully meets the requirements of clients.

The shell and tube heat exchangers are devices that allow transfer of heat between two fluids, without exposing them to a direct contact, thus preventing them to mix.

The choice of materials, in this field, is crucial and is made taking into account the chemical, physical characteristics of temperature and pressure of the fluid concerned and calculation codes used in the design.

The common features of the exchangers, in the standard version of the three product lines, are fixing the exchange tubes to the tube sheet by vacuum without welding and the use of the following materials: carbon steel for shell and head-shell covers, stainless steel for the tube bundle, carbon steel for all other internal parts (tie rods, diaphragm, etc.). The traditional Sicimi attitude of the "custom made" design and production, widely applied to the thermoregulation units, offers its customers, also in the case of heat exchangers, the chance to purchase an ad hoc product according to their specific needs.

Sicimi offers three product lines: IN LINE heat exchangers, BEM heat exchangers, BEU heat exchangers (removable tube bundle).

IN LINE heat exchangers

The IN LINE heat exchangers are shell and tube exchangers with tube bundle constructed in a fixed manner to facilitate their tube side assembly in line on the pipes by means of flange connections. This configuration of the tube bundle allows the cleaning of the inside of the tubes with mechanical systems, while the cleaning of the outer side can only be done through the use of chemical means.

In the construction of the exchanger IN LINE a single passage both of the fluid on the tube side and of the fluid on the shell side is provided for. This type of heat exchanger is comparable to the type of BEM exchanger without the two end caps, therefore the tube bundle inherits all the characteristics. In fact, even for the heat exchanger IN LINE, because of the rigid connection between the tube bundle and shell, where the diversity of materials used and / or the temperature difference between the two fluids exchanging heat are such as to create tensions between the tube bundle and shell, the installation of an expansion joint on the shell to absorb the different expansions and minimize tensions is provided for.

Standard constructive dimensions: diameters from Ø 2½ "to Ø 10", length of the tube bundle from 305 to 2745 mm.

Attachments on the shell: threaded sleeve or flat flange.

Possible constructive variants:

- Tube sheets made of stainless steel

- Full stainless steel construction

- Passage in the shell with or without diaphragms (for condensing steam)

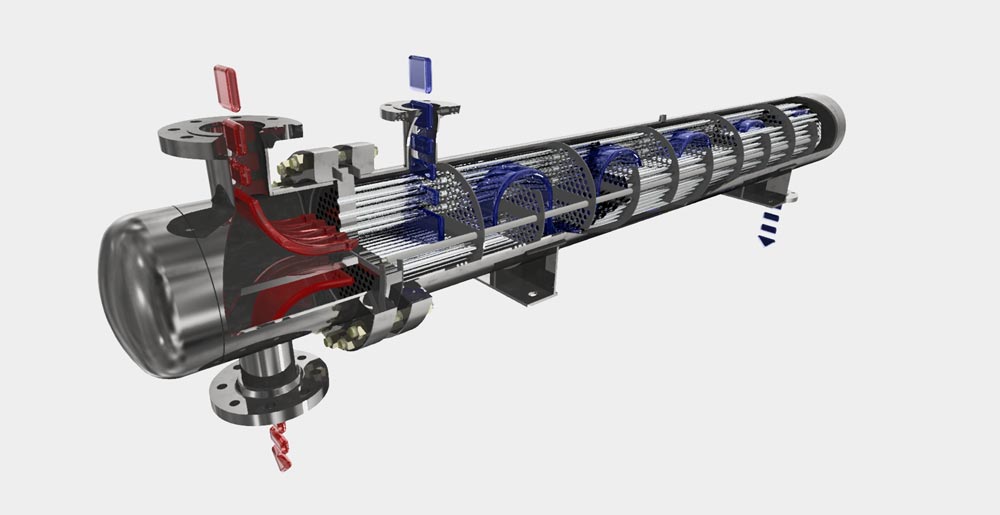

BEM heat exchangers

The BEM heat exchangers are shell and tube exchangers with tube bundle constructed in a fixed manner for easy mounting on skid. The tube bundle is fixed by mechanical rolling to two tube sheets, in turn welded to the shell of the heat exchanger. This configuration of the tube bundle allows the cleaning of the inside of the tubes with mechanical systems, while the cleaning of the outer side can only be done through the use of chemical means.

In the construction of the BEM exchanger a single pass of the shell side fluid and two or four passes of the fluid tube side are normally provided for. Given the rigidity of the connection between the tube bundle and shell, where the diversity of materials used and /or the temperature difference between the two fluids exchanging heat are such as to generate tensions between the tube bundle and shell, the installation of an expansion joint on the shell to absorb the different expansions and minimize tension is provided for.

Standard constructive dimensions: diameters from Ø 2½ "to Ø 10", length of the tube bundle from 305 to 2745 mm.

Attachments on the shell: threaded sleeve or flat flange.

Attachments on the head: with threaded tube, threaded sleeve or flat flange, disposed axially or radially.

Possible constructive variants:

- Tube sheets in stainless steel

- Heads and shell covers made of stainless steel

- Full stainless steel construction

- Passage in shell with or without diaphragms (for condensing steam)

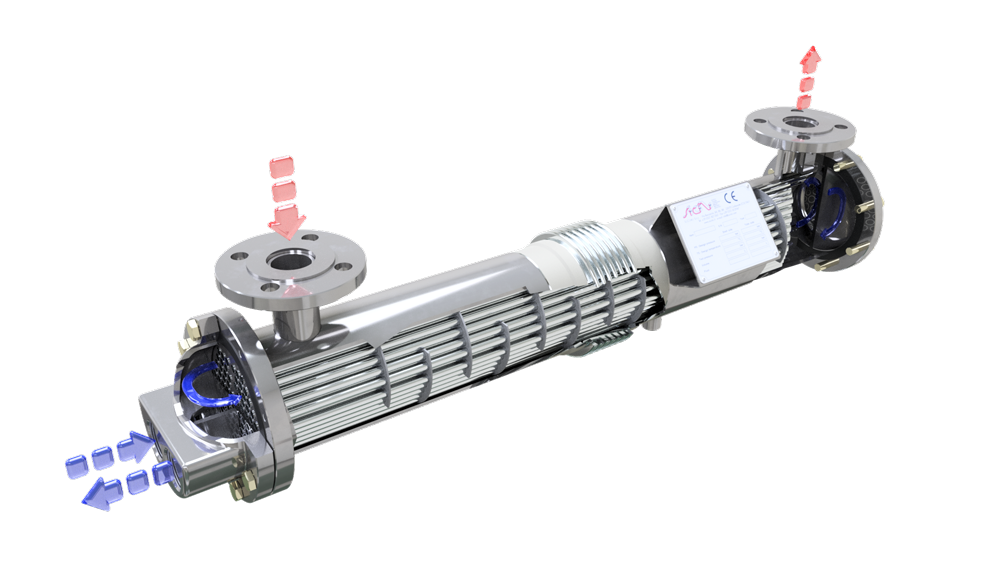

BEU heat exchangers

The BEU heat exchangers are shell and tube exchangers with tube bundle consisting of specially "U" shaped tubes fixed by mechanical rolling to only one tube sheet. This type of exchanger is designed and built with removable shell and tube to allow easy maintenance.

The cleaning of the tubes of the tube bundle must be done on both the inside and outside through the use of chemical means.

In the construction of the BEU exchanger a single pass of the shell side fluid and two or four passes of the fluid tube side are normally provided for.

The shell and tube is inserted into the tube bundle and is fixed to it with bolts. It can expand freely and therefore is not subject to tensions even in the presence of strong temperature differences between the fluids which exchange heat.

Standard constructive sizes: diameters from Ø 5 "to Ø 10", length of the tube bundle from 610 to 2800 mm.

Attachments on the shell: threaded sleeve or flat flange.

Attachments on the head: with threaded tube, threaded sleeve or flat flange, disposed axially or radially.

Possible constructive variants:

- Tube sheets in stainless steel

- Heads and shell covers made of stainless steel

- Full stainless steel construction

- Passage in shell with or without diaphragms (for condensing steam)